In the world of poker, the choice of playing cards is paramount. Serious players understand that the quality of the cards they use can significantly impact their game. Copag cards have emerged as one of the most trusted brands in the poker industry, known for their durability, precision, and overall quality. But have you ever wondered what Copag cards are made of? In this article, we’ll delve into the materials behind Copag playing cards, shedding light on what makes them the preferred choice of poker enthusiasts around the world.

The Birth of Copag

Copag, short for Companhia Paulista de Artes Gráficas, is a Brazilian company with a rich history dating back to 1908. They have been manufacturing playing cards for over a century, and their commitment to excellence has made them a staple in the world of professional poker. Copag wsop cards are used in some of the most prestigious poker tournaments globally, including the World Series of Poker (WSOP).

Composition of Copag Cards

Copag plastic cards are made using a unique blend of materials and a precise manufacturing process, ensuring a superior quality card that meets the demands of professional poker players and enthusiasts alike. The composition of Copag poker cards typically includes:

PVC (Polyvinyl Chloride): PVC is a common thermoplastic polymer used in the production of playing cards. It provides durability, flexibility, and resistance to water and other liquids, making it an ideal choice for manufacturing high quality playing cards.

Acetate: Copag plastic playing cards often contain acetate, another type of plastic material. Acetate is known for its transparency and glossiness, enhancing the visual appeal of the cards.

Cellulose Acetate: This is a type of synthetic material derived from cellulose, usually derived from wood pulp. Cellulose acetate is utilized in the creation of the card’s core, contributing to its rigidity and strength.

Copag Poker Playing Cards Manufacturing Process

The production of Copag cards involves a precise and intricate manufacturing process that ensures the final product meets the desired standards of quality and durability. The steps in manufacturing Copag cards typically include:

Material Preparation: The PVC, acetate, and cellulose acetate are prepared and mixed in specific ratios to create a uniform material suitable for card production.

Sheet Formation: The mixed materials are then transformed into thin sheets using specialized machinery. These sheets will serve as the base material for the playing cards.

Card Cutting: The sheets are cut into individual card sizes using precise cutting machines, forming the basic shape of the cards.

Printing and Design: The cards undergo printing, where the unique design, numbering, and suit symbols are applied using high quality ink and printing techniques.

Lamination: The cards are then laminated to enhance their durability, ensuring they can withstand frequent use without wearing or tearing easily.

Quality Control: Poker cards Copag go through rigorous quality control processes to ensure they meet the brand’s standards for excellence. Any defects or imperfections are identified and corrected during this stage.

Advantages of Copag Playing Cards Poker

Durability: Copag cards are highly durable and resistant to wear, making them suitable for extended use.

Flexibility: The PVC composition of Copag cards provides flexibility without compromising on strength.

Water Resistance: The materials used in Copag cards make them resistant to water and other liquids, preserving their quality even when exposed to moisture.

Longevity: Due to their durability, Copag plastic poker cards tend to last longer, providing value for the investment.

Fade Resistance: Another significant advantage of PVC plastic is its resistance to fading. Copag cards maintain their vibrant colors and sharp designs even after extended use, ensuring that they look as good as new for a long time.

Precision Printing: Copag employs state of the art printing techniques to ensure the highest level of precision in their card designs. This precision is essential in poker, where even the slightest variation in card markings can affect the outcome of a game.

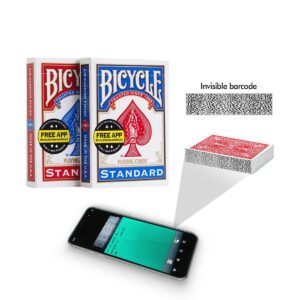

Security Features: Copag casino cards also include security features, such as UV ink markings, to prevent counterfeiting and cheating in professional poker tournaments.

Conclusion

Copag cards have become synonymous with quality and reliability in the poker world, and it’s no accident. Their choice of materials, primarily PVC plastic, provides the perfect combination of durability, flexibility, water resistance, fade resistance, and precision printing. These attributes ensure that Copag cards meet the demanding standards of professional poker players and enthusiasts alike.

At this point, do you want to ask, can such an excellent and trusted card in WSOP competitions be made into cheating card? Our company has Copag cards wholesale and many years of experience in marking playing cards. We can meet our customers’ needs for wholesale playing cards and Copag marked cards in large quantities. The cards we use are all imported from the original packaging, so please feel free to buy.